October 22, 2013

In this technical bulletin and video, we‘ll be using the JERZEES NuBlend 50/50 cotton/polyester fleece to demonstrate an effective method of optimizing printing on blended fleece. We’ve chosen the JERZEES brand because of the higher stitch density and smoother surface that allow for greater control of the printed ink film.

Blended fabrics offer some advantages over pure cotton. The polyester content reduces fibrillation, which can cause a print to look faded because of the little cotton fibers that stick up through the ink. This means you also get better ink coverage with 50/50. The polyester fibers also can give the garment a softer, more sheer feel. Lastly, polyester is known for its greater color durability, so clients interested in maintaining the color of their garments after repeated washings should consider blended garments.

To download the complete Tech Tips newsletter, click on the PDF link above.

April 5, 2024 | Process + Techniques

Why do we often struggle with some of the seemingly simplest things, like slathering screen-printing ink onto a decorated-apparel garment. Slathering so that it looks clean, bright, opaque and altogether attractive.

FULL STORY

March 13, 2024 | Process + Techniques

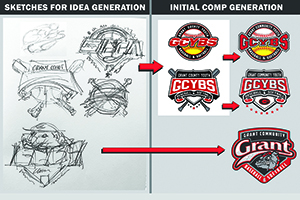

Wouldn’t it be wonderful if there was a secret formula for designing a best-selling T-shirt for a sports team, a business or for your own pre-print line?

FULL STORY

January 25, 2024 | Process + Techniques

As is the case with any craft, when it comes to screen-printing T-shirts and other apparel the devil is in the details. The best art, the best press in the world will inevitably come up short if you don’t take care of the little things as well.

FULL STORY