January 9, 2017

Sheen is the reflection of light from a surface. The smoother the surface, the easier the light reflects, giving it a glossy-sheen look. The more angular or rough a surface is, the harder it is for light to reflect, thus giving it a dull or matte sheen.

Most ink comes in either a matte or glossy finish. You can take a glossy ink finish and add a dulling agent to make it a lower gloss or matte. However, it is difficult to make matte-finish ink look glossy without the addition of a clear gloss coat to smooth out the surface.

So, the real question is how many screens you want to use versus how many additives you want to use. If you have a matte ink and want to make it not so matte, you are going to need an extra screen to overprint clear gloss ink. If you have a gloss ink and want to make it lower sheen, most companies offer a dulling/matte additive (or a puff additive) that can be added to the ink. The dulling additive will, in effect, roughen up the surface of the ink giving it a lower light refraction and thus a lower sheen.

Typically, dulling agents are added to ink at around 5-7% by weight. What is important to note is that when making lower-sheen ink, you should write down the recipe and label the leftover ink. Also note what percentage the dulling agent was used on the job sheet in case of a re-order, or so that it doesn’t get used on another job where that effect is not desired.

Mark Brouillard is product manager for International Coatings. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

March 20, 2024 | Production

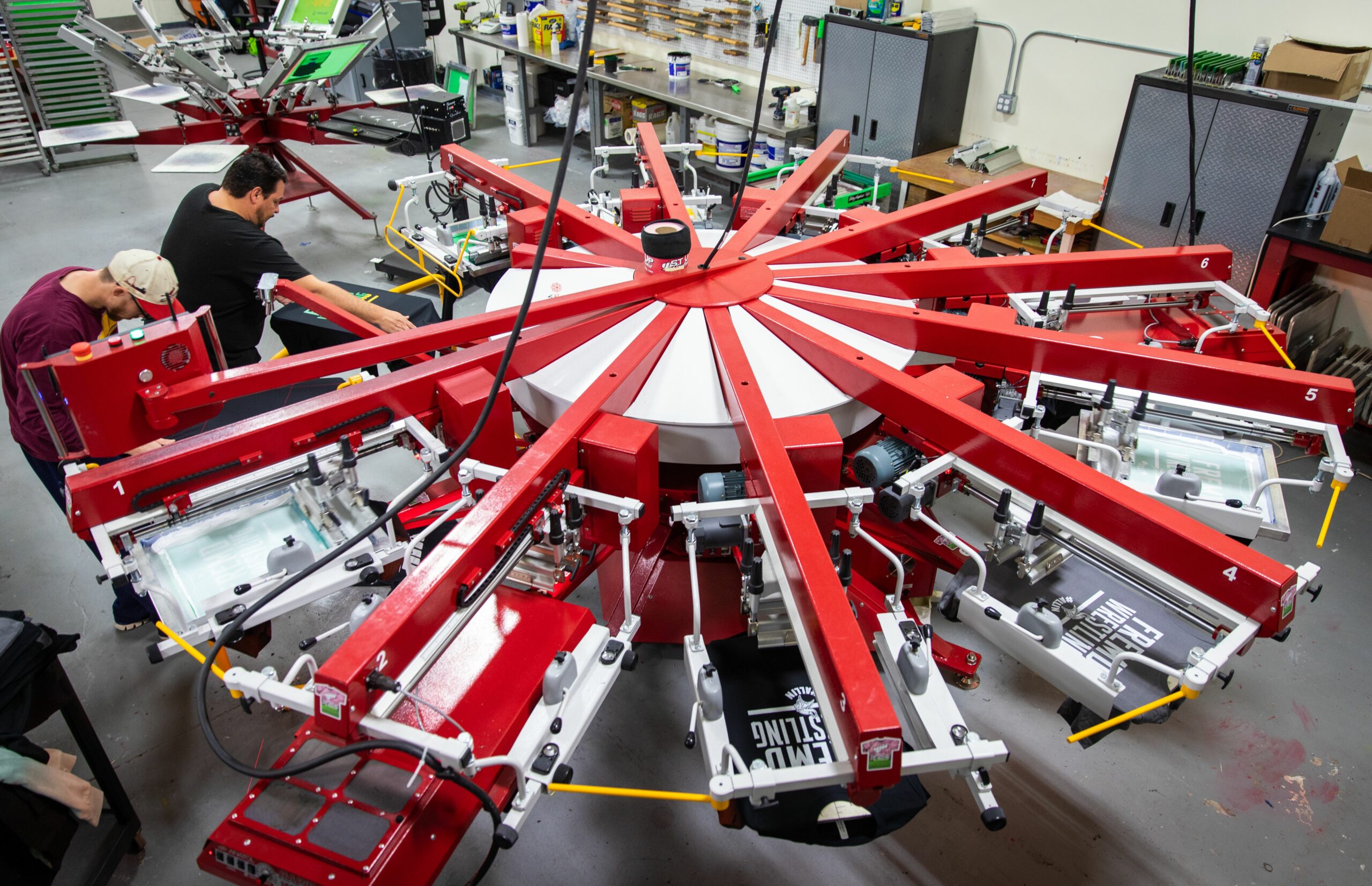

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY