September 14, 2015

By now, you’ve likely heard enough about the sublimation process to know that it involves a substance that changes from a gas to a solid without ever becoming a liquid.

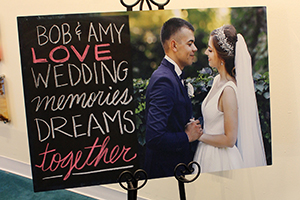

In the hard-surface sublimation industry, an image is printed onto transfer paper using dye-based ink and then transferred onto a specially coated surface with heat and pressure. Sublimation allows the reproduction of full-color images on a variety of surfaces, from T-shirts and mugs to metal prints and more. Instead of printing images directly on a surface, which may scratch easily, they are infused into a special coating that protects and preserves them for generations.

Here’s something you may not know: Adding hard-surface sublimation to your current business can be easy. All you need is a computer, printer with sublimation inks, transfer paper, heat press and hard-surface sublimation products.

Following is more information on essentials that are needed for this process.

Special Sublimation Printer: There are a variety of sublimation printers, but it’s important to have one that is compatible with dye-sublimation ink.

RIP Printing Software: Printing directly from programs like Adobe Photoshop doesn’t allow the color control that’s possible with RIP printing software. With it, you can develop your own color profile, which results in a better finished product.

Heat Press: Heat is what catalyzes the sublimation process, so a good heat press is vital.

Clay-Based Transfer Paper: Regular printing paper won’t hold the ink droplets and allow them to transfer into the coating. Clay-based paper will suspend the ink until it is transferred into the coating.

Special Inks: These inks are extra vivid and designed to last forever on hard surfaces.

Polyester Fabric: This can help wick away moisture that could damage your finished product.

Blowout Paper: This type of paper helps trap heat from the heat press and also protects your pad from damage by shielding it from extra ink that may escape during sublimation.

Heat Gloves: During a process that involves a heat element, it’s always a good idea to protect your hands.

Heat Tape and Tape Dispenser: Tape designed specifically for sublimation can be removed more easily than regular tape. Blue painters’ tape also can be used, is removed more easily and works especially well for large-format pieces.

PREVENTING CHIPPING

The market for hard-surface sublimation is expanding daily. There are numerous opportunities to grow and expand your business into new markets, such as personalized gifts, cell-phone cases, customized business products, schools, sports, professional photography, fine art and more.

If you’re already sublimating, here are a few helpful tips that will help you avoid chipping on aluminum or metal products.

1. When removing the protective film from your panels, do not use any hard or sharp tools that could possibly damage the surface or edges. Also, remove the film without digging into the sublimatable surface.

2. You may be able to save an aluminum panel with a chipped edge by sanding it, which also prevents future chipping. Use 220-grit sandpaper and a sanding block to sand the edges and round the corners. Sand in one consistent direction along the edge, holding the block at a 45-degree angle to the face of the aluminum in order to bevel the edge. Use even force and light pressure so that you don’t cause even more chipping.

3. If you experience chipping on small aluminum shapes (some keychains, keepsakes etc.), you can lightly sand the edge after sublimating to prevent chipping. If you sand before you sublimate, it may cause delamination. Sand the item in a different location than where your heat press is located to prevent dust, which may cause other sublimation issues.

4. When applying tape before pressing your panel, apply it to the opposite sides, but not the corners of the transfer paper. Use two or three pieces of tape on the sides of the panel close to the corner. This will hold the transfer in place and still make it easy to pull off. Once removed from the heat press, take the transfer off as soon as possible by gently pulling where the transfer paper is attached to the panel.

5. Handle all panels with care, especially when preparing them for pressing. Use extra care with hot aluminum panels, especially around the edges.

6. Never lean panels against a wall. This can cause them to bow when they are displayed. Store larger panels on a flat surface before displaying them. When hanging panels, make sure they have enough support so that they don’t fall and get chipped.

Sublimation is an art, and with practice you consistently can produce quality results. By applying the above best practices for preventing chipping, you can increase your business by successfully sublimating on hard-surface products.

Alesha Yaney is communications specialist for Unisub. For more information or to comment on this article, email Alesha at alesha.yaney@unisub.com.

Suggested Reading:

Like this article? Read these and other digital decorating articles at impressionsmag.com:

April 12, 2023 | Sublimation

As you work toward becoming an experienced dye-sublimation apparel, general merch or customized promotional items decorator, you may come across one or more obstacles, like your transfers coming out blurry, dull or faded.

FULL STORY

June 1, 2022 | Sublimation

How many times have you wished that you could sublimate a product that wasn’t polymer-based or polymer-coated.

FULL STORY

October 8, 2021 | Sublimation

I think the philosophy of lagniappe should be taught at every school and practiced by every business. A French word meaning “unexpected extra gift,” lagniappe often is used in Louisiana. In fact, sublimation decoration is a fantastic example of this.

FULL STORY